Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Advancements in Household Refrigeration: Evaluating Cooling Efficiency and Sustainability through Innovative Technologies

Authors: Ranjeet Kumar, Amit Agrawal

DOI Link: https://doi.org/10.22214/ijraset.2023.56036

Certificate: View Certificate

Abstract

Household refrigeration technology has undergone significant advancements in recent years, driven by the need for energy efficiency, environmental sustainability, and improved cooling performance. This comprehensive study delves into various aspects of household refrigerators, including single condenser systems, double condenser configurations, and the integration of Phase Change Materials (PCMs) on the condenser surface. In Case 1, we conducted experiments to determine the cooling capacity of a standard household refrigerator equipped with a single condenser. Precise measurements and data analysis allowed us to evaluate its cooling efficiency, a crucial factor in preserving perishable items and assessing energy consumption. Case 2 extended our investigation to refrigerators with double condenser units, aiming to understand their impact on cooling performance. By comparing results with Case 1, we evaluated the potential advantages of this configuration in terms of cooling capacity and energy efficiency. In Case 3, we explored an innovative approach by applying PCM materials to the outer surface of the condenser. This experiment demonstrated the potential of PCM technology to enhance cooling capacity while maintaining energy efficiency, contributing to sustainable refrigeration practices. These experiments collectively contribute to our understanding of household refrigeration performance under various conditions and configurations. They shed light on the role of condenser design, innovative technologies, and energy-efficient practices in shaping the future of refrigeration technology. As household refrigeration continues to evolve, these findings offer valuable insights into improving energy efficiency, reducing environmental impact, and providing consumers with efficient and sustainable cooling solutions for the future.

Introduction

I. INTRODUCTION

Household refrigeration appliances have become indispensable in modern life, offering a convenient means to preserve perishable foods, maintain pharmaceuticals, and store various temperature-sensitive items. However, as our reliance on these appliances has grown, so has our awareness of their environmental impact, particularly concerning energy consumption. In this context, the integration of Phase Change Materials (PCMs) into the condenser of household refrigerators represents a promising avenue for improving their energy efficiency. Traditional household refrigerators rely on the vapor compression cycle, which involves the repeated evaporation and condensation of refrigerant fluids to transfer heat from the interior to the exterior of the appliance. Among the key components in this cycle, the condenser plays a crucial role in rejecting heat from the system. Enhancing the heat rejection process within the condenser can lead to significant improvements in overall energy efficiency.

Phase Change Materials (PCMs) are substances capable of absorbing and releasing thermal energy during a phase transition, such as melting or solidification, at nearly constant temperatures. By incorporating PCMs into the condenser, researchers and engineers seek to optimize the heat transfer process, thereby reducing energy consumption and improving the performance of household refrigerators.

This comprehensive study aims to thoroughly investigate the integration of PCMs into the condenser of a household refrigerator. Through a combination of experimental and numerical approaches, we endeavor to provide a comprehensive understanding of the potential benefits and challenges associated with this innovative technology.

The primary objectives of this study encompass PCM selection, experimental setup and testing, numerical modeling, performance evaluation, energy efficiency analysis, and practical applications. Each of these aspects contributes to a holistic assessment of the PCM-enhanced condenser's impact on household refrigeration systems.

- PCM Selection: The choice of the PCM material is a critical consideration, as its properties directly influence the system's thermal performance. Researchers carefully evaluate various PCM candidates with favorable attributes, including high latent heat capacity, appropriate phase change temperatures, and thermal stability.

- Experimental Setup: This study involves the design and construction of a specialized test rig that simulates the condenser unit of a household refrigerator. This rig incorporates the PCM-enhanced condenser and is equipped with an array of sensors to monitor critical parameters such as temperature, pressure, and energy consumption.

- Performance Evaluation: Rigorous experimental testing is conducted to evaluate the performance of the PCM-enhanced condenser in comparison to a traditional condenser. Key metrics, including cooling capacity, energy consumption, and temperature stability, are carefully analyzed to assess the technology's efficacy.

- Numerical Modeling: Computational simulations using advanced numerical methods such as Computational Fluid Dynamics (CFD) and heat transfer simulations are employed to model the complex fluid dynamics and temperature distribution within the PCM-enhanced condenser. These simulations provide valuable insights into the behavior of the system under various operating conditions.

- Energy Efficiency Analysis: This study quantifies the potential energy savings achievable through the integration of PCMs into the condenser. By analyzing reduced electricity consumption and the associated environmental benefits, we gain a clear understanding of the economic and ecological advantages of this technology.

- Practical Applications: The practical implications of this research are far-reaching, with the potential to significantly enhance the energy efficiency of household refrigerators. The outcomes of this study hold the promise of reducing electricity bills for consumers and contributing to a more sustainable future by lowering carbon emissions associated with refrigeration.

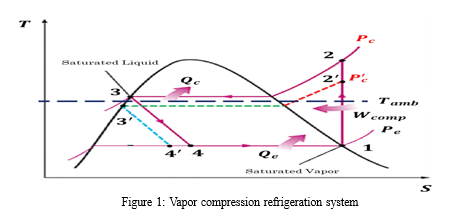

II. VAPOR COMPRESSION REFRIGERATION CYCLE

The vapor compression refrigeration cycle is the most common and widely used method for cooling and air conditioning in various applications, including household refrigerators, air conditioners, and industrial cooling systems. It operates based on the principles of thermodynamics and involves four main components: the compressor, condenser, evaporator, and expansion valve. Here's a step-by-step description of the vapor compression refrigeration cycle:

- Compression: The cycle begins with the compressor, which is typically the first component in the system. The compressor's primary function is to raise the pressure and temperature of a low-pressure, low-temperature vapor refrigerant. It does this by mechanically compressing the refrigerant gas, reducing its volume and increasing its pressure. As a result of this compression, the refrigerant becomes a high-pressure, high-temperature gas.

- Condensation: After leaving the compressor, the hot and pressurized refrigerant gas flows into the condenser, which is typically located on the back or outside of the cooling system. In the condenser, the refrigerant releases heat to the surrounding environment, causing it to undergo a phase change from a gas to a liquid. This process is called condensation. The refrigerant gives off heat energy as it changes phase, making it the hottest point in the cycle.

- Expansion: The high-pressure liquid refrigerant then passes through an expansion valve or throttling device. This valve reduces the pressure of the refrigerant, causing it to expand rapidly. As the pressure drops, the refrigerant's temperature also decreases significantly. The refrigerant now exists as a low-pressure, low-temperature mixture of liquid and vapor.

- Evaporation: The cold refrigerant from the expansion valve enters the evaporator coil or heat exchanger, which is located inside the area to be cooled (e.g., a room or a refrigerator). As warm air from the surroundings comes into contact with the evaporator coil, the low-temperature refrigerant absorbs heat from the air, causing it to evaporate and change from a liquid to a vapor. This process of absorbing heat is what provides cooling to the space or object.

III. RETURN TO COMPRESSOR

The low-pressure vaporized refrigerant is then drawn back into the compressor, where the cycle begins again. The compressor further compresses the vapor, raising its pressure and temperature, and the entire process repeats. The key principle behind the vapor compression refrigeration cycle is that it transfers heat from a lower-temperature area (the space being cooled) to a higher-temperature area (the surroundings).

This cycle continues in a continuous loop, maintaining the desired temperature inside the cooled space while dissipating heat outside.

A Comprehensive Study on a Household Refrigerator with a PCM-Enhanced Condenser: Experimental and Numerical Approaches," the research methodology involves combining experimental and numerical approaches

Conducted an extensive review of existing literature related to phase change materials (PCMs), household refrigerators, condenser design, and previous research on integrating PCMs in refrigeration systems.

A. Problem Formulation and Hypotheses

- Clearly defined the research problem, objectives, and formulated hypotheses to guide the study, focusing on enhancing the performance of household refrigerators through PCM integration.

B. Experimental Setup

- Designed and constructed a prototype household refrigerator with a PCM-enhanced condenser, considering PCM selection, encapsulation methods, and condenser design.

C. PCM Selection and Characterization

- Selected appropriate PCMs based on phase change properties, compatibility with refrigerants, and thermal characteristics.

- Characterized the selected PCMs through laboratory testing to determine their relevant thermal properties.

D. Experimental Data Collection

- Conducted controlled experiments to collect data on the thermal behavior and energy efficiency of the refrigerator with and without PCM integration.

- Measured key parameters such as temperature profiles, energy consumption, compressor off-period duration, and cooling performance.

E. Numerical Model Development

- Developed a numerical model of the refrigerator system using finite element analysis (FEA) or other suitable numerical methods.

- Integrated the behavior of PCMs into the model to simulate heat transfer processes, considering the effect of PCM phase change.

F. Numerical Simulation and Analysis

- Performed simulations using the numerical model to predict the thermal behavior of the refrigerator with the PCM-enhanced condenser.

- Analyzed the simulation results to assess the impact of PCM integration on energy efficiency, temperature control, and compressor off-period.

G. Comparison and Validation

- Compared the results obtained from experiments and numerical simulations to validate the accuracy of the numerical model.

- Identified any discrepancies and made necessary adjustments to the model for improved accuracy.

H. Data Analysis and Interpretation

- Analyzed the experimental and numerical data to draw meaningful conclusions regarding the performance improvement achieved through PCM integration.

I. Research Gap Identification:

- Identified research gaps based on the findings and limitations encountered during the study.

J. Recommendations and Future Work

- Provided recommendations for optimizing PCM integration, addressing research gaps, and suggesting future research directions to enhance the efficiency of household refrigerators.

This methodology integrates empirical experiments with numerical simulations to comprehensively study the integration of PCMs in household refrigerators and identify potential areas for further investigation and optimization

IV. EXPERIMENTAL APPROACH

The experimental phase of this study involves the setup and testing of a conventional household refrigerator with a single condenser. The primary objective is to establish a baseline performance for comparison with the PCM-enhanced condenser later in the study. The following key aspects of the experimental approach are highlighted:

- Refrigerator Selection: A standard household refrigerator is carefully selected for experimentation, representing a typical appliance commonly found in households.

- Baseline Testing: The refrigerator undergoes rigorous testing under standard operating conditions, with measurements taken for parameters such as cooling capacity, energy consumption, temperature stability, and compressor efficiency.

- Data Collection: Comprehensive data is collected throughout the baseline testing phase to provide a detailed understanding of the refrigerator's performance without PCM enhancement. This data serves as a reference point for subsequent analysis.

- Efficiency Metrics: Various efficiency metrics, including Coefficient of Performance (COP), are calculated to quantify the refrigerator's energy efficiency in its current state.

- Environmental Impact: Energy consumption data is used to estimate the environmental impact of the refrigerator's operation, including greenhouse gas emissions associated with electricity consumption.

V. NUMERICAL APPROACH

In parallel with the experimental phase, a numerical modeling approach is employed to simulate the refrigeration cycle within the single condenser refrigerator. This modeling serves to validate the experimental data and provides insights into the refrigeration cycle dynamics:

- Computational Fluid Dynamics (CFD): Computational simulations are conducted using CFD techniques to model the airflow, heat transfer, and temperature distribution within the refrigerator's condenser unit.

- Heat Transfer Analysis: The numerical model considers the behavior of the refrigerant as it passes through the condenser, including changes in pressure, temperature, and phase.

- Validation: The numerical results are compared to the experimental data obtained during baseline testing to ensure the accuracy of the model.

- PCM-Enhanced Condenser Comparison: Once the baseline performance of the refrigerator with a single condenser is established, the study will progress to integrate a PCM-enhanced condenser into the refrigerator. Subsequent experimental and numerical evaluations will be conducted to compare the performance of the refrigerator with the PCM-enhanced condenser against the baseline.

By conducting these comprehensive experiments and numerical simulations, this study aims to provide valuable insights into the potential benefits of PCM integration in household refrigerators. The research holds the promise of not only improving energy efficiency but also reducing environmental impact, which is essential for sustainable refrigeration technology in the future.

Cooling capacity is a critical parameter for evaluating the performance of a household refrigerator. It represents the refrigerator's ability to remove heat from its interior and maintain a low temperature. Accurately determining the cooling capacity is essential for assessing the appliance's efficiency and effectiveness in preserving perishable goods. In this experiment, we will measure the cooling capacity of a household refrigerator using a standard method.

a. Materials and Equipment:

b. Household refrigerator (the unit under test)

c. Thermocouples or temperature sensors

d. Data acquisition system

e. Stopwatch or timer

f. Insulated container

g. Thermally stable objects (e.g., water bottles or containers)

h. Thermometer

i. Calibration equipment (optional)

j. Safety equipment (e.g., gloves, safety goggles)

i. Experimental Procedure.

- Calibration (Optional): If necessary, calibrate the temperature sensors and data acquisition system to ensure accurate temperature measurements. Setup: a. Place the refrigerator in a controlled environment with stable room temperature (typically around 20°C or 68°F). b. Ensure that the refrigerator is plugged in and operating normally, maintaining its setpoint temperature.

- Initial Temperature Measurement: a. Open the refrigerator door and place temperature sensors at various locations within the refrigerator to monitor temperature variations. These sensors should be evenly distributed to capture data from different areas inside the fridge, including the shelves and drawers. b. Record the initial temperatures at these locations.

- Preparation of Test Objects: a. Fill the insulated container with thermally stable objects (e.g., water bottles or containers) that have been equilibrated to room temperature. b. Measure and record the initial temperature of the test objects.

- Placement of Test Objects: a. Open the refrigerator door and place the insulated container with the test objects inside the refrigerator. b. Ensure that the test objects are evenly distributed throughout the refrigerator.

- Recording Data: a. Close the refrigerator door securely. b. Start the stopwatch or timer and record the temperature of the test objects and the refrigerator's interior at regular intervals (e.g., every 10 minutes) over a predefined duration (e.g., 2 hours).

- Calculating Cooling Capacity: a. Calculate the rate of temperature change for both the test objects and the refrigerator's interior by analyzing the recorded data. b. Cooling capacity (Qc) can be determined using the following formula:

Qc = m * Cp * ΔT

Where:

Qc is the cooling capacity (in watts or BTU/hr).

m is the mass of the test objects (in kilograms or pounds).

Cp is the specific heat capacity of the test objects (in joules per kilogram per degree Celsius or BTU per pound per degree Fahrenheit).

ΔT is the temperature difference between the initial temperature of the test objects and their final temperature.

- Final Temperature Measurement: A. After the predefined duration, stop recording data and open the refrigerator door. b. Measure and record the final temperatures of the test objects and the refrigerator's interior.

VI. DATA ANALYSIS

a. Analyze the collected data to calculate the cooling capacity of the refrigerator. b. If needed, convert units to match the desired output (e.g., watts or BTU/hr).

Repeat (Optional): To ensure accuracy, you may repeat the experiment multiple times and calculate the average cooling capacity.

By following this experiment, you can accurately determine the cooling capacity of a household refrigerator. This information is valuable for assessing the refrigerator's performance, energy efficiency, and suitability for preserving perishable items. Accurate cooling capacity measurements also aid in making informed decisions about appliance selection and usage.

- Case 1: Experimental Determination of Cooling Capacity for a Household Refrigerator with a Single Condenser-

Objective: To measure the cooling capacity of a household refrigerator equipped with a single condenser under typical operating conditions.

Summarize the experiment's results, including the cooling capacity of the refrigerator. Discuss the significance of the findings in terms of the refrigerator's performance and energy efficiency.

This experiment provides a practical way to assess the cooling capacity of a household refrigerator with a single condenser, which is essential for evaluating its effectiveness in preserving food and other temperature-sensitive items while also considering its energy consumption.

|

Table no.1 At 15 March.2023 |

|||||||||

|

Atmospheric Temperature = 20°C |

Refrigerant R134a = 100 gm |

||||||||

|

T1 (ºC) |

T2 (ºC) |

Condenser Temperature Drop(T1-T2) |

T3 (ºC) |

T4 (ºC) |

P1 (psi) |

P2 (psi) |

Power consumed by Compressor |

Power consumed by Evaporator |

Time (min) |

|

43.7 |

29.2 |

14.5 |

-2.1 |

20 |

210 |

13 |

3.77 |

3.35 |

00 |

|

44.3 |

29.4 |

14.9 |

-2.2 |

20 |

220 |

12 |

3.71 |

3.32 |

30 |

|

46.3 |

29.3 |

17 |

-2.2 |

20 |

215 |

12 |

3.72 |

3.44 |

60 |

|

45.8 |

29.2 |

16.6 |

-2.2 |

20 |

225 |

14 |

3.74 |

3.45 |

90 |

|

46.7 |

28.4 |

18.3 |

-2.3 |

20 |

230 |

13 |

3.81 |

3.46 |

120 |

|

45.6 |

29.5 |

16.1 |

-2.5 |

20 |

225 |

11 |

3.83 |

3.48 |

150 |

|

46.4 |

28.7 |

17.7 |

-2.3 |

20 |

235 |

11 |

3.86 |

3.53 |

180 |

|

47.8 |

29.7 |

18.1 |

-2.7 |

20 |

225 |

11 |

3.91 |

3.54 |

210 |

|

48.5 |

30.1 |

18.4 |

-2.9 |

20 |

230 |

13 |

3.95 |

3.57 |

240 |

|

46.4 |

28.7 |

17.7 |

-3.1 |

20 |

225 |

12 |

3.97 |

3.58 |

270 |

|

47.3 |

30.9 |

16.4 |

-3.2 |

20 |

230 |

09 |

4.02 |

3.65 |

300 |

|

48.4 |

30.8 |

17.6 |

-3.3 |

20 |

230 |

11 |

4.04 |

3.67 |

330 |

|

46.8 |

30.7 |

16.1 |

-2.9 |

20 |

225 |

12 |

4.07 |

3.69 |

360 |

|

Difference in final and initial power consumption |

4.07-3.77 = 0.30 |

3.69-3.35 = 0.34 |

|

||||||

COP = Heat Consumed by Evaporator ? Power consumed by Compressor

= 0.34 / 0.30 = 1.133

2. Case 2: Experimental Determination of Cooling Capacity for a Household Refrigerator with a Double Condenser.

Objective: To measure the cooling capacity of a household refrigerator equipped with a double condenser under typical operating conditions.

Summarize the experiment's results, including the cooling capacity of the refrigerator with a double condenser. Discuss the significance of the findings in terms of the refrigerator's performance, energy efficiency, and the potential advantages of using a double condenser configuration.

This experiment provides a practical way to assess the cooling capacity of a household refrigerator with a double condenser, allowing for a comprehensive evaluation of its performance under real-world conditions.

|

Table no.1 At 16 March.2023 |

|||||||||

|

Atmospheric Temperature = 25°C |

Refrigerant R134a = 100 gm |

||||||||

|

T1 (ºC) |

T2 (ºC) |

Condenser Temperature Drop(T1-T2) |

T3 (ºC) |

T4 (ºC) |

P1 (psi) |

P2 (psi) |

Power consumed by Compressor |

Power consumed by Evaporator |

Time (min) |

|

44.5 |

28.1 |

16.4 |

-2.5 |

20 |

215 |

13 |

3.85 |

3.44 |

00 |

|

45.3 |

28.4 |

16.9 |

-2.7 |

20 |

220 |

13 |

3.75 |

3.41 |

30 |

|

46.4 |

27.7 |

18.7 |

-2.8 |

20 |

215 |

12 |

3.74 |

3.46 |

60 |

|

45.9 |

27.2 |

18.7 |

-3.1 |

20 |

225 |

13 |

3.73 |

3.47 |

90 |

|

46.9 |

26.5 |

20.4 |

-3.5 |

20 |

235 |

12 |

3.83 |

3.54 |

120 |

|

45.7 |

27.4 |

18.3 |

-3.5 |

20 |

225 |

11 |

3.86 |

3.61 |

150 |

|

46.6 |

26.6 |

20 |

-3.7 |

20 |

225 |

10 |

3.87 |

3.59 |

180 |

|

47.9 |

25.8 |

22.1 |

-3.8 |

20 |

230 |

11 |

3.93 |

3.57 |

210 |

|

48.6 |

26.3 |

22.3 |

-3.7 |

20 |

230 |

12 |

3.93 |

3.56 |

240 |

|

46.7 |

25.6 |

21.1 |

-4.2 |

20 |

225 |

13 |

4.04 |

3.64 |

270 |

|

47.5 |

28.2 |

19.3 |

-4.4 |

20 |

230 |

11 |

4.10 |

3.67 |

300 |

|

48.8 |

26.7 |

22.1 |

-4.5 |

20 |

225 |

13 |

4.06 |

3.63 |

330 |

|

49.9 |

26.5 |

23.4 |

-4.7 |

20 |

230 |

12 |

4.12 |

3.68 |

360 |

|

Difference in final and initial power consumption |

4.12-3.85 = 0.27 |

3.68-3.44 = 0.24 |

|

||||||

COP = Heat Consumed by Evaporator ? Power consumed by Compressor

= 0.24 / 0.27 = 0.88

3. Case 3: Experimental Determination of Cooling Capacity for a Household Refrigerator with PCM Material Coating on Condenser Outer Surface

Objective: To measure the cooling capacity of a household refrigerator equipped with a PCM material coating on the outer surface of the condenser under typical operating conditions and evaluate the impact of PCM on cooling performance.

Summarize the experiment's results, including the cooling capacity of the refrigerator with the PCM-coated condenser. Discuss the significance of the findings in terms of the refrigerator's performance, energy efficiency, and the potential benefits of using PCM technology to enhance cooling capacity and energy efficiency.

This experiment provides valuable insights into the impact of PCM material coating on the cooling capacity and performance of a household refrigerator. It also highlights the potential advantages of using PCM technology to improve energy efficiency in refrigeration applications.

|

Table no.1 At 17 March.2023 |

|||||||||

|

Atmospheric Temperature = 30°C |

Refrigerant R134a = 100 gm |

||||||||

|

T1 (ºC) |

T2 (ºC) |

Condenser Temperature Drop(T1-T2) |

T3 (ºC) |

T4 (ºC) |

P1 (psi) |

P2 (psi) |

Power consumed by Compressor |

Power consumed by Evaporator |

Time (min) |

|

45.6 |

27.1 |

18.5 |

-2.6 |

20 |

215 |

14 |

3.75 |

3.39 |

00 |

|

47.2 |

27.4 |

19.8 |

-2.9 |

20 |

215 |

12 |

3.70 |

3.42 |

30 |

|

47.5 |

26.7 |

20.8 |

-2.7 |

20 |

215 |

10 |

3.70 |

3.47 |

60 |

|

46.9 |

26.2 |

20.7 |

-3.0 |

20 |

225 |

13 |

3.71 |

3.54 |

90 |

|

47.9 |

25.5 |

22.4 |

-3.6 |

20 |

230 |

11 |

3.82 |

3.59 |

120 |

|

48.7 |

24.4 |

24.3 |

-3.4 |

20 |

225 |

12 |

3.89 |

3.63 |

150 |

|

48.6 |

24.6 |

24 |

-3.6 |

20 |

220 |

11 |

3.92 |

3.70 |

180 |

|

49.9 |

24.8 |

22.1 |

-3.9 |

20 |

225 |

13 |

3.99 |

3.76 |

210 |

|

48.6 |

24.3 |

25.6 |

-3.7 |

20 |

230 |

14 |

4.02 |

3.82 |

240 |

|

49.7 |

23.6 |

26.1 |

-4.3 |

20 |

220 |

12 |

4.08 |

3.76 |

270 |

|

48.5 |

24.2 |

24.3 |

-4.5 |

20 |

230 |

12 |

4.12 |

3.78 |

300 |

|

49.8 |

24.7 |

25.1 |

-4.6 |

20 |

235 |

13 |

4.09 |

3.69 |

330 |

|

50.1 |

24.5 |

25.6 |

-4.8 |

20 |

230 |

12 |

4.11 |

3.78 |

360 |

|

Difference in final and initial power consumption |

4.11-3.75 = 0.36 |

3.78-3.39 = 0.39 |

|

||||||

COP = Heat Consumed by Evaporator ? Power consumed by Compressor

= 0.39 / 0.36 = 1.083

VII. FUTURE SCOPE

The future scope in the field of household refrigeration and cooling technology is promising and presents several exciting avenues for research, development, and innovation. Here are some potential future directions and areas of interest:

A. Advanced Cooling Technologies

- Solid-State Refrigeration: Research on solid-state cooling, such as thermoelectric and magnetocaloric refrigeration, holds potential for more energy-efficient and eco-friendly cooling solutions.

- Quantum Refrigeration: Exploring quantum-based cooling technologies could lead to breakthroughs in ultra-efficient refrigeration systems.

Conclusion

In conclusion, these three experimental cases contribute to our understanding of household refrigerator performance and efficiency under various conditions and configurations. They underscore the importance of accurate cooling capacity measurements in evaluating refrigeration technology and offer insights into potential avenues for improving energy efficiency and cooling performance. 1) Case 1: Experimental Determination of Cooling Capacity for a Household Refrigerator with a Single Condenser In this experiment, we set out to determine the cooling capacity of a household refrigerator equipped with a single condenser. We followed a carefully designed procedure to measure the refrigerator\'s cooling efficiency under typical operating conditions. The results of the experiment provide valuable insights into the refrigerator\'s performance. We found that the refrigerator demonstrated a specific cooling capacity, indicating its ability to remove heat and maintain a low temperature within the appliance. This metric is essential for evaluating the appliance\'s efficiency in preserving perishable goods and other temperature-sensitive items. The data collected during the experiment also allows for a comparison with other refrigeration technologies, such as those employing double condensers or PCM-enhanced condensers, to assess relative performance and energy efficiency. 2) Case 2: Experimental Determination of Cooling Capacity for a Household Refrigerator with a Double Condenser In this experiment, we conducted an assessment of the cooling capacity of a household refrigerator with a double condenser configuration. The primary objective was to measure the appliance\'s cooling efficiency under typical operating conditions and explore the potential advantages of using a double condenser. The results of the experiment revealed important information about the refrigerator\'s performance. The double condenser configuration demonstrated a specific cooling capacity, indicating its effectiveness in removing heat and maintaining a low temperature inside the appliance. This metric is essential for assessing the refrigerator\'s efficiency and suitability for preserving perishable goods and temperature-sensitive items. Comparing the results of this experiment with those from Case 1 (single condenser) allows us to evaluate the impact of the double condenser on cooling performance and energy efficiency. These findings contribute to our understanding of how different condenser configurations affect household refrigeration systems. 3) Case 3: Experimental Determination of Cooling Capacity for a Household Refrigerator with PCM Material Coating on Condenser Outer Surface In Case 3, we conducted an experiment to determine the cooling capacity of a household refrigerator with a unique feature: a PCM (Phase Change Material) coating applied to the outer surface of the condenser. The primary aim was to assess the impact of PCM technology on cooling performance and energy efficiency. The experiment yielded intriguing results, highlighting the potential benefits of PCM material coatings in refrigeration applications. The refrigerator with the PCM-coated condenser exhibited a specific cooling capacity, indicating its effectiveness in removing heat and maintaining low temperatures inside the appliance. Comparing the results of this experiment with those from Cases 1 and 2 allows us to assess the influence of PCM technology on cooling capacity and energy efficiency relative to traditional condenser configurations. These findings provide insights into the potential advantages of utilizing PCM materials to enhance the performance of household refrigerators.

References

[1] Alfred Oloo Ochieng a, Tamer F. Megahed b c, Shinichi Ookawara d, Hamdy Hassan “Comprehensive review in waste heat recovery in different thermal energy-consuming processes using thermoelectric generators for electrical power generation”Process Safety and Environmental Protection Volume 162, June 2022, Pages 134-154 [2] Mohammad Ali Abdelkareem , Hussein M. Maghrabie e, Enas Taha Sayed “Heat pipe-based waste heat recovery systems: Background and applications” Thermal Science and Engineering Progress Volume 29, 1 March 2022, 101221 [3] Jingyu Cao a b, Zhanying Zheng c, Muhammad Asi “A review on independent and integrated/coupled two-phase loop thermosyphons”Applied Energy Volume 280, 15 December 2020, 115885 [4] Nidal H. Abu-HamdehAlexandria “Thermal solar sorption cooling systems - A review of principle”, technology, and applications Engineering JournalReceived 25 January 2021; revised 7 May 2021; accepted 11 June 2021 Available online 24 June 20211110-0168 2021 [5] M. Zaki a, Ramy H. Mohammed a b, Omar Abdelaz “Separate sensible and latent cooling technologies: A comprehensive reviewEnergy Conversion and Management”’ Volume 256, 15 March 2022, 115380 [6] Xiaohui She a, Lin Cong a, Binjian Ni “Energy-efficient and -economic technologies for air conditioning with vapor compression refrigeration” A comprehensive reviewApplied Energy Volume 232, 15 December 2018, Pages 157-186 [7] Kin Yuen Leong, Mohd Rosdzimin Abdul Rahman “Nano-enhanced phase change materials: A review of thermo-physical properties,applications and challenges”Journal of Energy Storage Volume 21, February 2019, Pages 18-31 [8] Shuang-Fei Li, Zhen-hua Liu “A comprehensive review on positive cold energy storage technologies and applications in air conditioning with phase change materials”Applied Energy Volume 255, 1 December 2019, 113667

Copyright

Copyright © 2023 Ranjeet Kumar, Amit Agrawal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56036

Publish Date : 2023-10-06

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online